Why J-J Hooks Barrier?

J-J Hooks – A Brand You Can Trust

Specified across North America, the patented J-J Hooks Precast Concrete Safety Barrier system is both the most economical and easiest to install, with fast connections, no loose hardware, and rapid reconfiguration. More than 16 million linear feet have been produced worldwide.

The Benefits of Choosing Patented J-J Hooks Safety Barrier

Fastest Setting Times on the Market

“Save time with J-J Hooks and meet your deadlines with ease. Faster and easier than the competition.”

- Quick connections: Self-aligning – automatically “hooks” into place – no jostling

- No confusion: Identical ends means there’s no need to turn the barrier

- Simple installation: Vertical lift simplifies installation, allowing mid-section removal

- Fast reconfiguration: Remove one barrier without disturbing adjacent barrier

Easiest System Available

“Eliminates the hassle of complex connection systems.”

- No pins, bolts, or loose hardware: No loose parts to track

- Smaller installation crews: Installs with a 3-person crew – an equipment operator and two ground crew installers.

- Reduces traffic congestion: The J-J Hooks connection has a wider-angle variable than other systems, allowing for a tighter radius and smoother transitions.

Most Economical Barrier System

“The lowest installation costs of any system.”

- Reduces installation costs: Faster installation and smaller crews

- Eliminates replacement costs: No rusted nuts and lost or stolen bolts

- Reduces workers’ compensation claims: No hands caught between barrier segments

Most Secure Barrier Connection System

“Rest easy knowing your site won’t be prone to vandals and thieves.”

- Theft-proof connection: No loose hardware

- No loss of structural integrity due to missing hardware

- Tested: Meets MASH Test Level 3 crash test criteria

- Approved: For every state in the Mid-Atlantic region

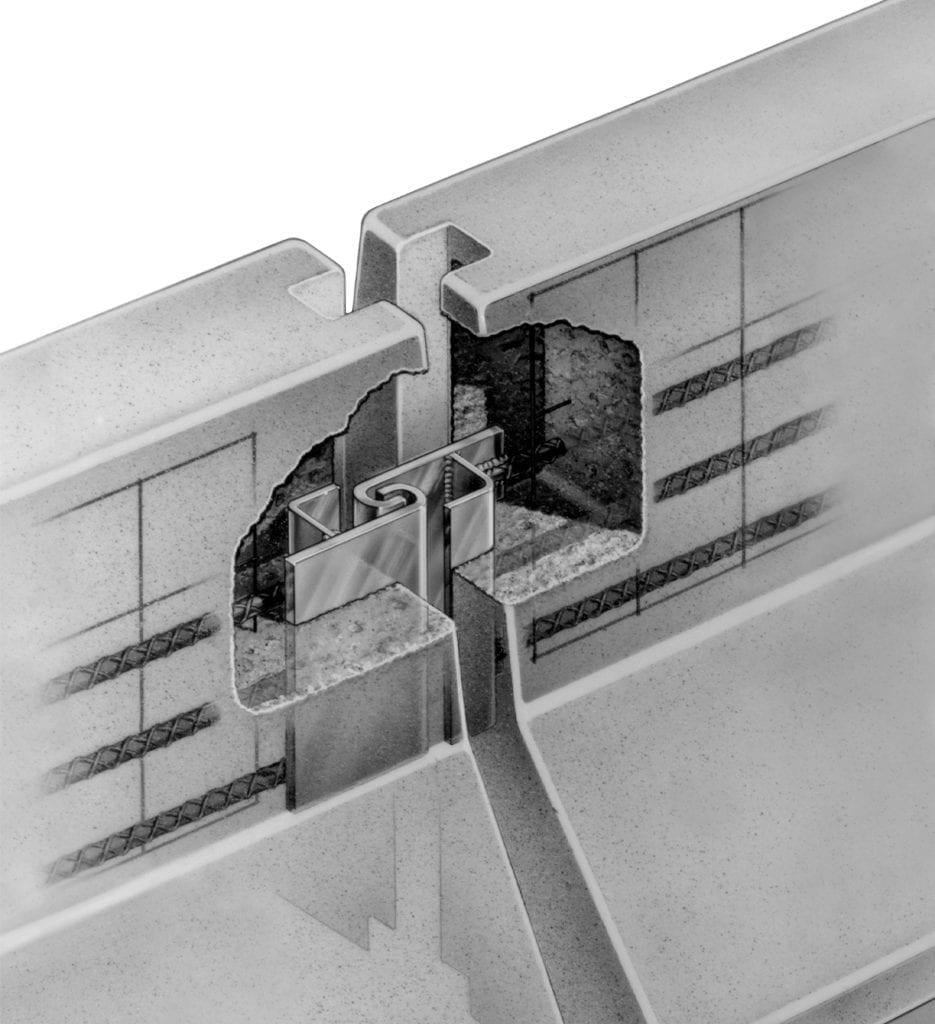

J-J Hooks Barrier Connection

How They Connect

The J-J Hooks connection consists of two identical J-shaped steel hooks connected internally with multiple steel rebars welded to each J-Hook. This provides a continuous steel connection throughout the barrier installation. To attach the barrier ends, one barrier is lowered vertically next to an adjacent barrier. With minimal guidance, the self-aligning connection automatically “hooks” into place. Workers’ hands are protected because there is no need to place them between barriers to make the connection.

The integrated barrier connection means there is no issue with lost or stolen hardware. J-J Hooks barrier provides a continuous positive shear connection throughout the barrier system. The J-J Hooks are identical on both ends of the barrier. There are no left or right pieces, simplifying installation. Due to vertical lift, a single barrier can be removed without disturbing adjacent barriers.

Precast Concrete Barrier Profiles

The J-J Hooks barrier system is approved in both the Jersey Shape and the F-Shape with a 24″ wide base under MASH Level 3, and accepted by the FHWA on all federal projects. Some states have modified the standard dimensions of Jersey and F-Shape barriers, making precast barrier profiles unique in those states.

J-J Hooks concrete barriers are available in 10’ 12’ and 20’ sections. The 20’ (6.1 meter) sections are approved with additional reinforcing. Transition sections, bridge barriers and other special designs are available.

Jersey Barriers

Jersey Barriers

This design, known as the “New Jersey Type” or “Jersey Walls,” was originally developed by the New Jersey State Highway Dept. This barrier type:

- Absorbs the impact of a moving vehicle

- Quickly slows down the impacting vehicle

- Guides the vehicle back to its original line of travel, enabling the operator to retain control (depending on the impacting angle of vehicle).

These characteristics are the result of the following primary features:

- The large mass of reinforced concrete, which absorbs impact and resists penetration through a controlled deflection of the barrier.

- A gently sloped ramp, which tends to raise the impacting vehicle. Contact with the undercarriage causes the vehicle to slow down rapidly, while being returned safely to its original line of travel.

Naturally, as with any other type of barrier, some vehicular damage can be expected in a vehicle/barrier collision. This fact has led to much research on various profiles.

F-Shape Barriers

F-Shape Barriers

The F-Shape is a new generation of the safety shape that is intended to further limit vehicle damage. The lower sloped face redirects vehicles under low-impact conditions. During moderate to severe impacts, some energy is dissipated when the vehicle is lifted off the pavement. The F-Shape reduces this lift, which promotes better vehicle stability while maintaining vehicle redirection. In crash tests, the F-Shape has proven more successful in preventing rollover of smaller vehicles. The F-Shape has been found to be more effective overall than the Jersey Shape barrier.